Do You Ever Feel Like Your A/C Needs A Little Help?

An A/C precooling system from Mistcooling.com is the answer you have been looking for!

- We have options available for units of all size: Residential, commercial, & industrial.

- Reduce your energy bill.

- Maximize cooling power.

- Lengthen the life of HVAC components by reducing their workload.

- Easy to install and maintain.

- Multiple control options give you worry-free automation.

How Does HVAC Pre-cooling work?

By combining 2 scientific principles:

- Enthalpy of Vaporization: When water evaporates, latent heat energy is used to break the bonds between water molecules, allowing them to transition from a liquid state to a gaseous state. As a result, the surrounding environment is cooled.

- The principle of increased surface area: A larger surface area allows more molecules to escape into the air, facilitating a faster evaporation process.

The result:

By creating an ultra-fine mist of water droplets, measured in mere microns, almost all of the water is exposed to the air immediately. The resulting evaporation is so fast that a tremendous amount of heat is absorbed in the process. As that cooled air passes through your condenser coils, it removes heat more effectively than hot air.

Innovative HVAC Misting Systems for Enhanced Cooling Efficiency

- Experience unparalleled cooling efficiency with our Commercial Pre Cooling System designed to enhance the performance of your air conditioning units and industrial equipment.

- This advanced cooling solution reduces energy consumption by up to 30%, allowing your equipment to operate more efficiently while extending its lifespan.

- By optimizing turbine performance and keeping heat-generating machinery at peak performance, our pre-cooling system ensures maximum output even during extreme heat conditions.

- Ideal for use with any air-cooled AC, refrigeration units, cooling towers, and other equipment, this system not only delays the need for additional cooling equipment but also improves the coefficient of performance (COP).

- Upgrade options include thermostats, controllers, and industrial-grade filters, providing you with a customized cooling solution tailored to your needs. Enjoy reduced head pressure, lower output temperatures, and extended equipment life with our hassle-free, efficient pre-cooling system.

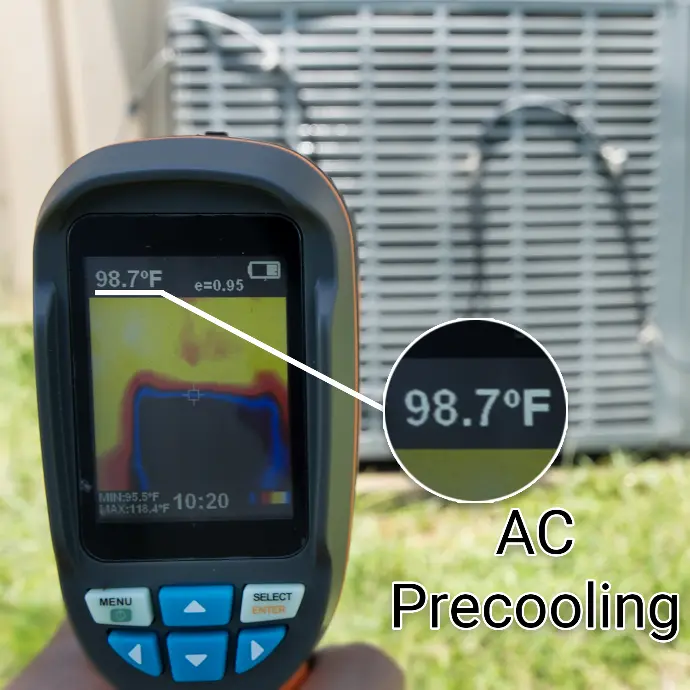

Studying the Performance of AC Pre-Cooling Systems in the Texas Heat

Our team conducted an expert evaluation to assess the efficiency of the mist cooling AC precooling system in the scorching Texas heat. The temperature readings captured in the images below provide a clear comparison of the conditions before and after the installation of the cooling system.

Before AC Pre-Cooling System

After Pre-Cooling System

Features of the Commercial Pre Cooling System | Air Conditioner Cooler:

Energy Efficiency: Reduces equipment energy costs by up to 30%.

Extended Equipment Lifespan: Allows equipment to run more efficiently, prolonging its life.

Enhanced Performance: Optimizes turbine performance and maintains peak output.

Reduced Cooling Load: Delays or eliminates the need for additional cooling equipment.

Increased Capacity: Ensures air-cooled equipment operates at full capacity even during extreme heat.

Customizable Options: Includes options for thermostats, controllers, and filters.

Easy Integration: Can be used with any air-cooled AC/refrigeration unit, cooling towers, and other equipment.

Reduced Maintenance: Offers upgrade options for industrial sediment and scale prevention filters.

Operational Savings: Reduces head pressure, lower output temperature, energy consumption, and "time-on" cycles.

Enhanced Cooling Efficiency: Increases the coefficient of performance (COP) and extends the life of the condenser.

Residential AC Pre-cooling System | Residential AC Misting System

24 AC Voltage

Easy DIY Install

Automatic Operation

Helps Cut Electricity Usage by up to 30%

Installing Your Own DIY Air Conditioner Pre-Cooling System

The Cool Energy AC Mister is designed for easy, hassle-free installation, allowing you to quickly enhance your AC unit's efficiency and enjoy the benefits of reduced energy costs and improved cooling performance.

For detailed visual guidance, refer to the installation video available on the product page.

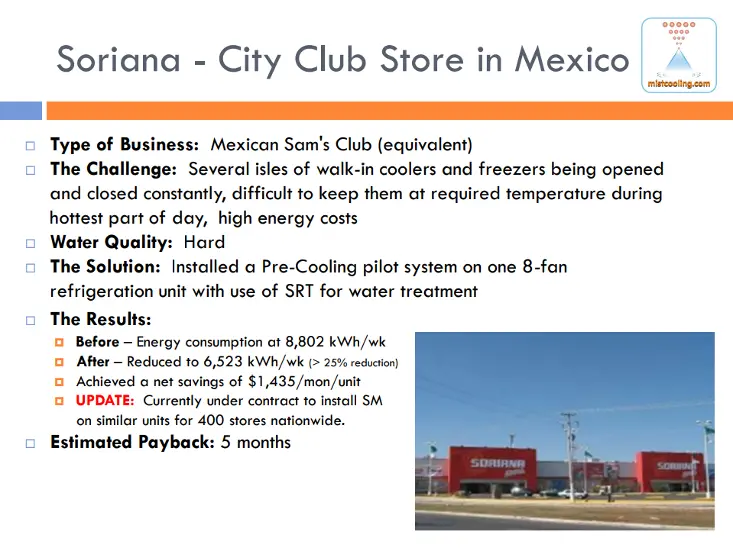

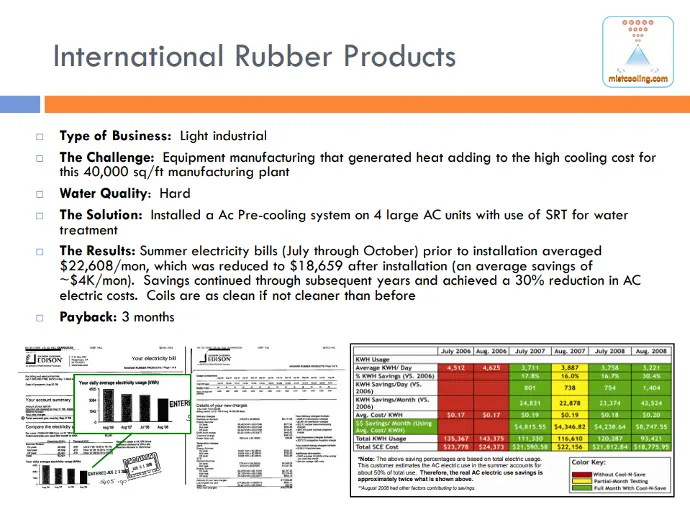

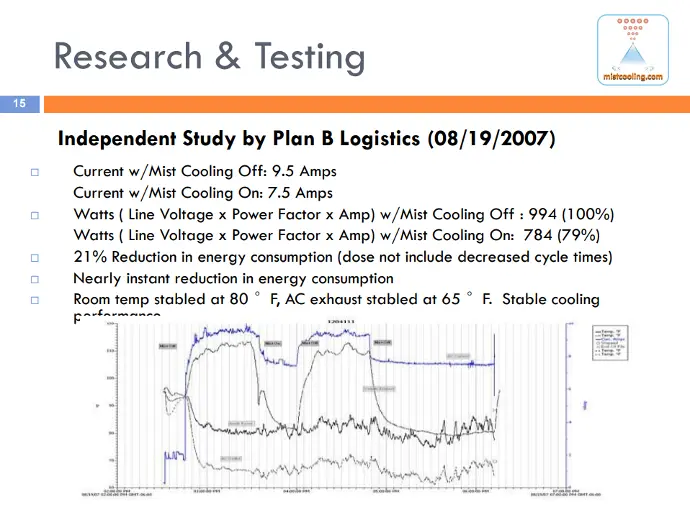

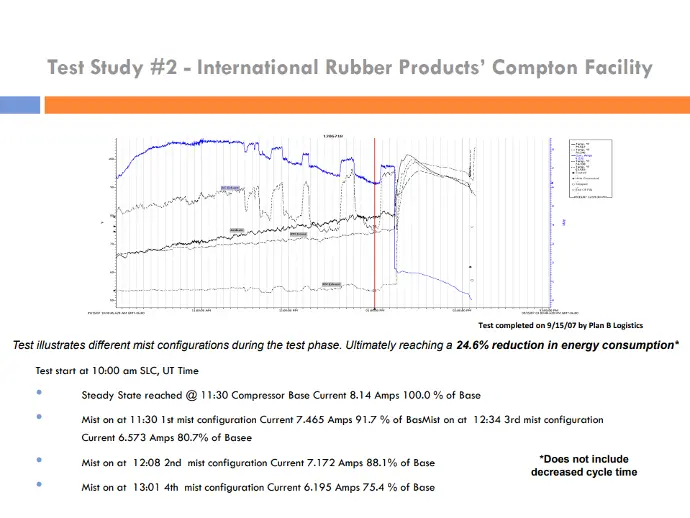

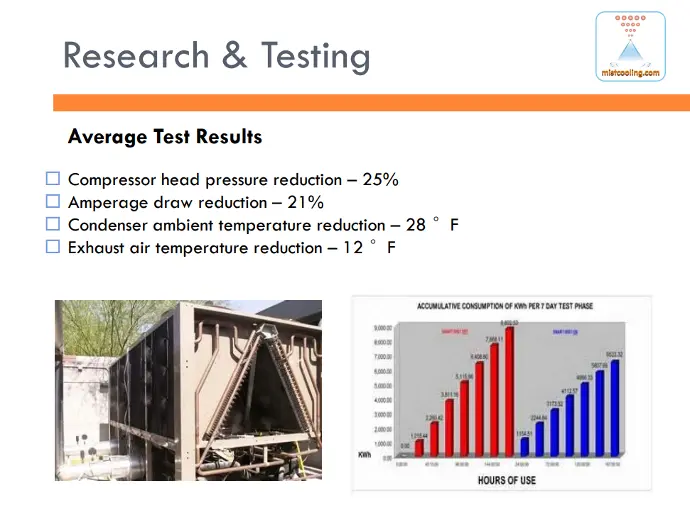

Commercial & Industrial Case Studies

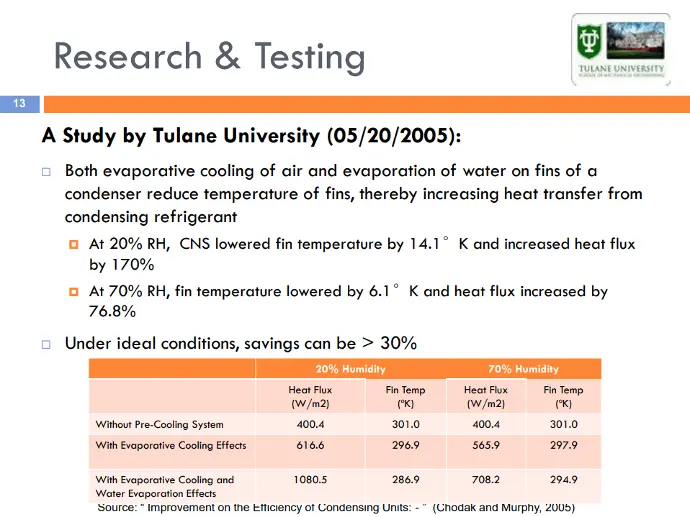

Technical Research - Proof of Concept

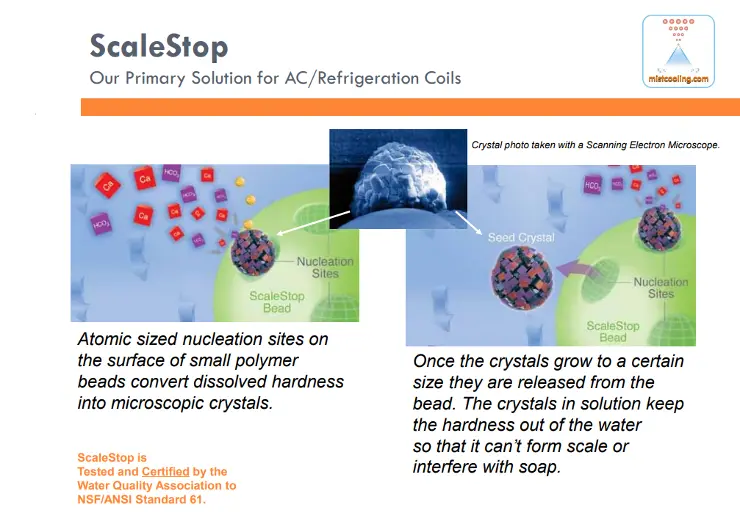

Addressing The Scale Issue

An Obstacle That Can Be Overcome

A Common Question?

"What about the scale and minerals in the water? Won't they build up on the condenser coils? Won't it lead to corrosion, clogging, and shorten the life of the equipment?"

The Solution - Proper Filtration

To mitigate the risk, we employ advanced water treatment solutions. Our sediment filtration system removes impurities and most minerals that can cause scale buildup and corrosion, while the anti-scale function in our filtration prevents mineral deposits from sticking to your coils, even if they get through the filter. This safeguards your investment by minimizing maintenance needs and extending the lifespan of both the misting and A/C components.

Designing Your HVAC Precooling System

For Residential A/C:

- Our DIY kits come with everything you need to install the system- filter, feed line, control box, lines, fittings, and nozzles.

- No pump is needed, simply hook it up to your water source.

- The control box ties directly into the 24VDC signal wire solenoid at the condenser, so it only mists when your unit is on.

- Each nozzle effectively covers approximately a 1 foot radius from its center point. For smaller units, this usually means just one nozzle on each side of the condenser. For units that are 3 feet or taller, 2 nozzles may be needed on each side.

- The pre-built kits come in multiple sizes, so you can choose the option that matches your needs.

For Commercial and Industrial Applications:

- Water Source Requirements: Most of our misting pumps require a water pressure of 40PSI - 60PSI coming into the pump while it is running. Having too little pressure and flow could shorten the pump's life span, lead to unwanted vibrations, or even prohibit operation.

- Power Source Requirements: We have pumps available for 110VAC, 220VAC, and 460VAC power types. Knowing what type of power you have available will be important when choosing the right pump(s).

- Determining Pump Location: Power and water supplies are normally present near HVAC equipment, so finding a central location for the pump is usually easy. Unlike many of our competitors, our pumps come standard with a rust-proof, weather-rated enclosure, so it is okay for the pump to be out in the elements, as long as it will not be flooded or submerged. The pump should also be able to sit level.

- Water Quality and Filtration: Excellent filtration is a high priority in HVAC precooling. For systems between .15 - 2 GPM, the individual sediment and scale filters are both recommended. For larger systems, the industrial sediment and scale filter is required.

- System Control Options: Relay controls that rely on a thermostat signal are a common configuration. Many customers also add our built-in thermostat to their pre-cooling pump so that it only activates when ambient temperatures are above a certain level. Our goal is full automation without waste.

- Tubing: Flexible tubing is easy to work with and suitable for most small-to-medium commercial systems. A common layout is displayed in the pictures and videos at the top of this page. Magnetic attachments are available to prevent drilling or installing fasteners near sensitive areas. For larger industrial applications, flow rates, pressures, and heat characteristics may require the use of stainless steel tubing.

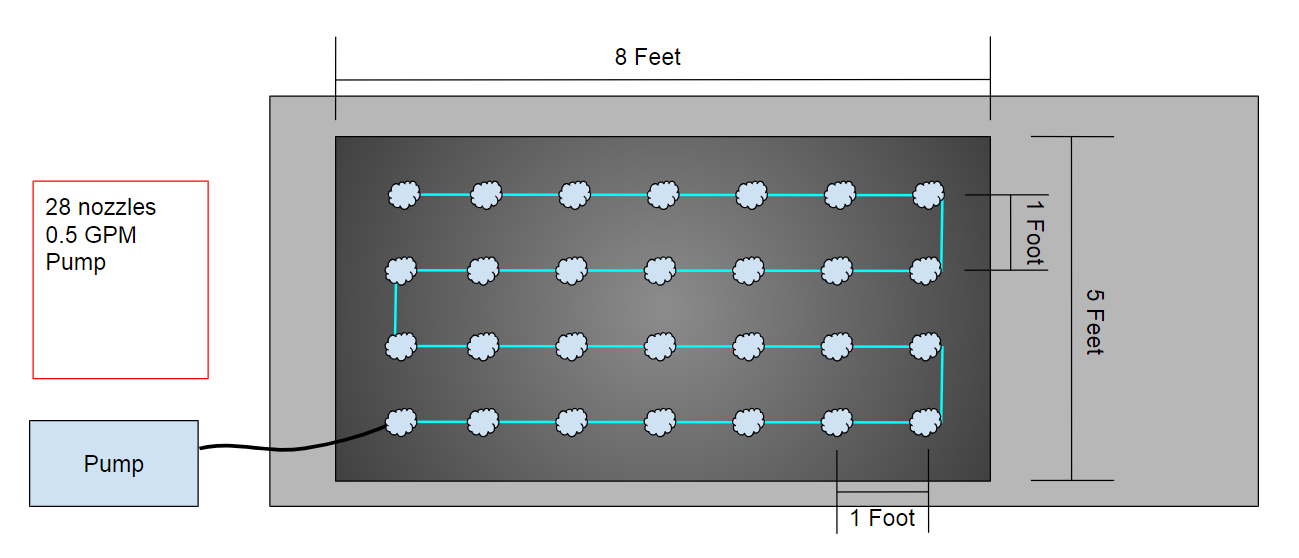

- Measuring for Your System: 1 foot spacing between nozzles, both horizontally and vertically, is recommended for each condenser coil face. For Example:

See All Mistcooling Applications

Residential Misting Systems

Is your backyard paradise too hot to enjoy? A high-quality misting system from Mistcooling is the answer you have been looking for!

Learn More

Restaurant Misting Systems

Maximize the value of your outdoor spaces by keeping your customers cool! Many restaurant owners have discovered significant business increases after installing a misting system from Mistcooling!

Learn More

Mosquito Misting Systems

Do you find that you can't sit outside and enjoy a good book because you're too busy swatting away mosquitoes? We have the solution for you!

Portable Misting Systems

Need to stay cool on the move? Maybe you're going somewhere that doesn't have a water or power source? We carry a variety of portable solutions designed for sports, outdoor events, camping, golf carts, and more!

Learn More

Pool Coolers

Does taking a dip in your pool feel more like a warm bath than a refreshing outdoor swim? Our pool coolers are a low-cost solution that uses your pool's natural pressure and a little applied physics to cool it down!

Learn More

Warehouse Cooling

Are your workers feeling sluggish from the heat, but you know that a full HVAC system is too expensive? Mist cooling systems can cool indoor spaces, protect your workers' health, and increase productivity without emptying your wallet.

Learn More

Special Effects Misting

Would a rolling fog be the perfect finishing touch for your landscape? Do you want to create your own personal rainbow? Misting systems can provide stunning visual effects for a wide variety of purposes!

Learn More

Barn Cooling / Animal Cooling

If you're hot, they're hot? Well, not anymore! Keep your animals and livestock safe and cool with a misting system from Mistcooling!

Learn More

A/C Pre-Cooling Systems

Dry, 105°F air isn't very effective at removing heat from your condenser coils! Stay cooler this summer! Increase your HVAC efficiency and cut energy costs by adding an A/C Precooling system from Mistcooling!

Learn More

Produce Case Misting Systems

No one wants to buy dry, shriveled produce! Keep your fruits and vegetables clean and fresh with our food-grade produce case misting systems!

Learn More

Humidification - Greenhouse/Data Centers

Use a Humidification system from Mistcooling to maintain a target humidity level in your facility.

Learn More

Roof Cooling

Did you know that your roof could be one of the primary heat sources driving your energy costs up? With a roof cooling system from Mistcooling, you can remove that heat from the equation!

Learn More

Dust Suppression

Whether you are building something, or tearing something down, dust can be a big problem! Catch it with mist and bring it to the ground with a Mistcooling dust suppression system!

Learn More

Odor Control

Is the EPA after you because your water treatment facility or garbage center is stinking up the nearby neighborhood? We can get those odors under control!

Learn More

Sanitization

With a recent, global pandemic in the rearview mirror, the importance of sanitization has never been clearer! Who needs to scrub when a sanitizing mist can do the work for you?!

Learn MoreFAQ's for Commercial AC Pre-Cooling System

Q1: What is included in the Commercial Pre Cooling System package?

A1: The package includes the misting pump, tubing, tees, nozzles, and options for upgrade filters and controllers, ensuring a complete setup for optimal cooling efficiency.

Q2: How does the system reduce energy consumption?

A2: By pre-cooling the air entering the AC unit, the system reduces the workload on the equipment, leading to up to 30% energy savings.

Q3: Can this system be used with any air-cooled AC unit?

A3: Yes, the pre-cooling system is compatible with any air-cooled AC, refrigeration unit, cooling towers, and other equipment.

Q4: What are the benefits of using this system for my HVAC equipment?

A4: Benefits include reduced energy costs, extended equipment life, optimized performance, reduced maintenance, and improved cooling capacity.

Q5: Are there upgrade options available?

A5: Yes, there are upgrade options for thermostats, controllers, industrial sediment filters, and scale prevention filters to enhance system performance.

Q6: How easy is it to install the Commercial Pre Cooling System?

A6: The system is designed for easy installation and integration with existing HVAC equipment, with detailed manuals and video guides provided.

Q7: What maintenance is required for the pre-cooling system?

A7: Minimal maintenance is required, especially with the optional filters that help prevent sediment and scale buildup. Regular checks and occasional cleaning of the nozzles are recommended.

Q8: How does this system improve the efficiency of my air conditioning unit?

A8: By reducing the air intake temperature, the system lessens the workload on your AC unit, allowing it to operate more efficiently and effectively, even during peak heat conditions.

Q9: Where can I find more information or get assistance with installation?

A9: Detailed manuals and installation videos are available on the product page. You can also book a call with an expert for personalized assistance.

Q10: What is the return policy for this product?

A10: The product comes with a hassle-free return policy, ensuring customer satisfaction and support in case of any issues.

Q11: How often should the filter be changed in the misting system?

A11: The water filter should be changed every 3 to 6 months, depending on the water quality. For areas with hard water, a TAC Scale Free filter is recommended and lasts up to 2 years.

Q12: What maintenance is required for the mist pump?

A12: Regular maintenance includes changing the oil every 500 hours of operation or once per season, cleaning or replacing nozzles as needed, and ensuring the filter is clean and functional.

Q13: What safety precautions should be taken during installation?

A13: Ensure the pump is installed on a flat, dry surface away from direct elements. Do not run the pump dry, and always use the provided filter to prevent clogging. Follow the detailed installation and maintenance instructions provided in the manual.

Q14: Can the mist pump handle liquids other than water?

A14: The pump is designed for water use only. For other liquids, please consult with the supplier to ensure compatibility and safety.

Q15: What is the warranty on the 1500 PSI mist pump?

A15: The high-pressure mist pump comes with a 1-year warranty. The warranty covers defects in material and workmanship but does not cover damage due to misuse, improper installation, or lack of maintenance.

Q16: How should the system be winterized?

A16: Before temperatures drop below freezing, turn off the water supply, unplug the pump, and drain all water from the filter and tubing. Store the pump indoors if possible, or use compressed air to blow out excess water from the pump and lines to prevent freezing damage.

Q17: What should be done for de-winterization?

A17: Check and replace the inlet filter, change the oil in the pump, reinstall any removed fittings, flush the system to remove air and debris, and check for non-working nozzles, cleaning or replacing them as needed.